A Second Chance For Tyres

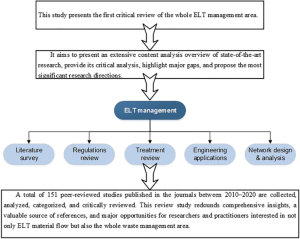

As the demand for tires continues to grow, there is a growing need for solutions to dispose of end-of-life tyres (ELT). Currently, approximately 1 billion end-of-life tires are generated every year and they are estimated to remain in landfills and stockpiles worldwide until their natural disposal is no longer possible.

There are many environmental and social benefits of a more circular approach to tire management. These benefits can be achieved through the development of a sustainable supply chain, the use of renewable resources, and by encouraging the reuse and recycling of tyres.

One solution is to recycle tyres, and this is being pursued by several firms. Among them, the Swedish firm Wastefront AS has developed a method to recover carbon black from waste tires that can be incorporated into new tyres. The company says that it uses a pyrolysis process that heats the tires to 450 degrees and produces no carbon emissions. The result is a rubber powder that can be recycled into biofuels and other products.

A Second Chance For Tyres: The Future of Recycling Used Tyres

Another Canadian firm, Phoenix Innovation Technology, has also developed a process to devulcanize rubber that breaks up sulfur bonds. It claims to be able to produce rubber from recycled tires at rates up to 8 million pounds per year.

The regenerated rubber will be used in new tires, as well as for crumb rubber in the construction industry. The company is collaborating with Michelin to develop a process that will allow them to make new tires using only recycled material, keeping 33 million barrels of oil out of the manufacturing process.

Unlike many polymers, rubber cannot be simply melted down and re-used as is, so it must be vulcanized — cross-linked with sulfur — in order to impart necessary mechanical properties. Until now, there hasn’t been a viable process to break up this complex molecule and return it to its original form.

To address this challenge, Michelin is working with Lehigh Technologies to develop a system that allows them to make new tires from recycled rubber and other materials. This could save them 33 million barrels of oil in production over the life of the project, according to Cyrille Roget, Michelin’s director of technical and innovation communications.

But it won’t be easy to get all the raw materials together. Michelin is enlisting the help of a number of partners to help build the eco system that will make this happen.

This system will enable them to keep the materials they need close by, which will cut down on the transportation of the raw material and reduce fossil fuel usage. That will mean less energy spent in transport, which can offset greenhouse gas emissions.

In addition to reclaiming the raw materials, this system also provides Michelin with greater control over their supply chain. The system can be used to manufacture tires that use a wide variety of materials, such as wood, trees and other sustainable resources.